What Sustainability Means to Us

At MODULO, sustainability is more than just a responsibility – it is the foundation of our operations. From sourcing natural materials to energy-efficient processes, we are committed to leaving a positive impact on our environment and communities.

ISO Recertifications

MODULO successfully obtained ISO 9001 (Quality Management), ISO 45001 (Occupational Health and Safety Management) and including ISO 14001 certification, which underscores our commitment to environmental management systems. By adhering to these rigorous standards, we systematically assess, monitor, and reduce our environmental footprint, ensuring continuous improvement and compliance with global best practices, the recertifications in 2023, further demonstrating our commitment to maintaining high standards of quality and workplace safety.

Carbon Footprint Measurement and Five-Year Target Plan

MODULO has taken significant steps to measure its carbon footprint, laying the foundation for future reduction strategies. This effort supports the company’s goal of tracking and mitigating its environmental impact in alignment with global sustainability standards.

Our company began accounting for greenhouse gas (GHG) emissions in 2020 with the support of a third-party specialist.

Emissions have been benchmarked against both annual production and annual turnover, allowing for more accurate tracking of progress.

Starting with 2023, MODULO will prepare annual reports on its CO2 emissions, this report being the second in the series.

As a result of these measurements, MODULO is committed to developing a comprehensive five-year target plan to reduce its carbon footprint further. This plan will include periodic reviews to ensure that progress is maintained, and additional reduction opportunities are identified.

Natural Gypsum

In spite of common industry practice, we avoid using fly ash or synthetic gypsum and instead source natural gypsum (98 % purity) from quarries just outside our Turda plant. This local sourcing strategy lowers raw-material costs and cuts transport distances, resulting in a significantly smaller carbon footprint.

Natural gypsum extraction and processing consume far less energy than the power-intensive methods required to produce synthetic gypsum, which translates into substantially lower CO₂ emissions. By working with nearby suppliers, we also maintain tight quality oversight and traceability, ensuring each batch meets our purity standards without the need for extensive post-mining treatment.

Beyond its environmental benefits, natural gypsum has a long history of trusted use across industries. Its sustainable and accessible nature makes it an ideal material for our production, ensuring we deliver high-quality products while minimizing environmental impact.

The Challenges We Face

Sustainability is a journey filled with challenges. From reducing CO2 emissions to adopting renewable energy, we continue to innovate while adapting to evolving global standards.

- Reducing carbon footprint further.

- Transitioning to renewable energy sources.

- Ensuring compliance with ESG standards.

Transparency and Accountability

We believe that transparency builds trust. Our Sustainability Report is a testament to our commitment to accountability, showcasing our progress, goals, and areas of improvement.

Commitment to a Green Future:

To reinforce the 2025 and 2030 sustainability ambitions, MODULO established clear objectives for 2024 focused on advancing sustainable practices.

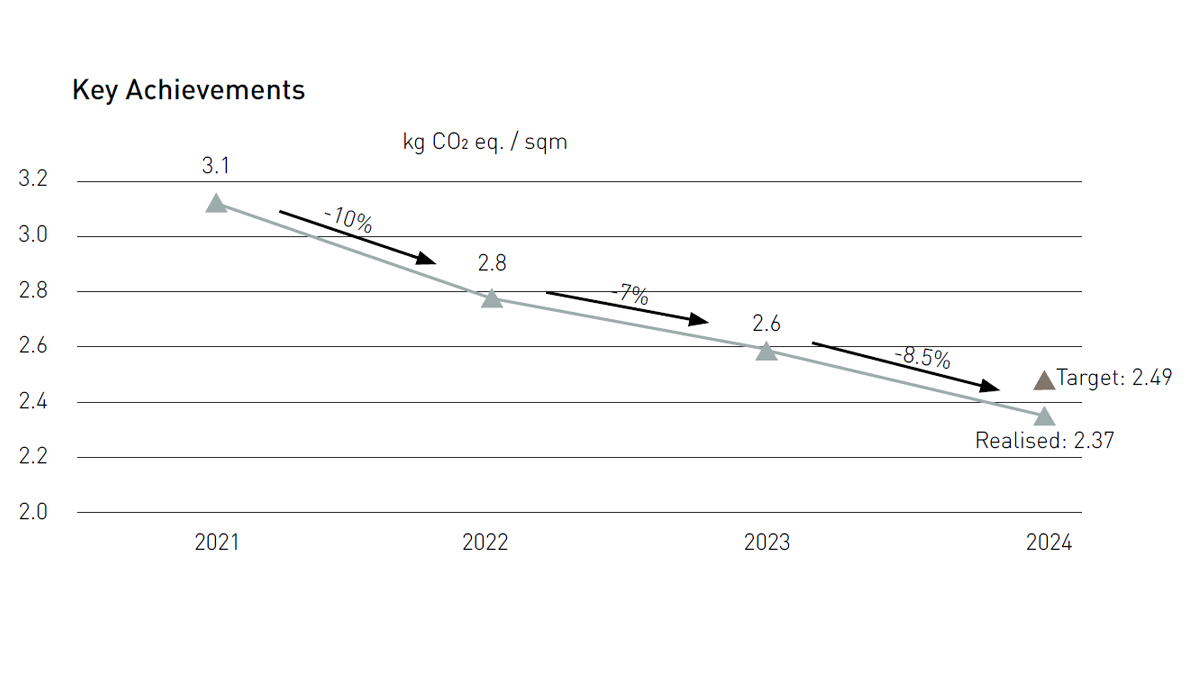

Reduction of CO₂ Emissions

MODULO targeted a further 3% reduction in CO₂ emissions per square meter by end of 2024. The last reported figure (2023) was 2.6 kg CO₂/sqm for cement-based products.

In 2024 emissions decreased by 8.5%, reaching 2.37 kg CO2 Eq. /sqm (outperforming the 2.497 kg CO2 Eq. /sqm target).

Implementation of Energy-Saving Measures

In 2024, MODULO achieved a 10% reduction in overall energy consumption (outperforming the 5% target) by installing two new compressors (one with variable speed), optimizing gas and electricity use on all curing lines, and upgrading to LED lighting throughout the facility. Only the best-insulated curing system is now used, further lowering gas consumption.

Transition to Renewable Energy

Starting November 2024, 30% of all electricity consumed at MODULO comes from renewable sources.The company has completed feasibility studies for installing photovoltaic panels, submitted EU funding applications, and plans to implement the project by 2026.

Promotion of Sustainable Practices

MODULO continued internal campaigns to reduce waste, encourage carpooling, switch off idle equipment, and unplug unused devices. The company’s waste recycling rate increased to 95% in 2024, up from 75% in prior years.

Carbon Footprint Recalculation

In 2024, MODULO completed a new carbon footprint calculation in collaboration with Servelect, using updated energy coefficients and incorporating, for the first time, production waste into the final figures. This more comprehensive methodology ensures greater accuracy and reflects the full environmental impact of our operations. MODULO will continue to publish annual carbon footprint assessments, using them as a strategic tool to monitor progress and guide the next phase of our five-year emissions reduction plan.

2021: Highest emissions recorded, at 3.1 kg CO₂ Eq. / sqm of product.

2022: Emissions decreased by 9.7%, reaching 2.8 kg CO₂ Eq. / sqm.

2023: Emissions further decreased by 7.1%, reaching their lowest point yet at 2.6 kg CO₂ Eq. / sqm.

2024: Emissions decreased by 8.5%, reaching 2.37 kg CO2 Eq. / sqm.

Why Sustainability Matters

It is my pleasure to introduce our second annual Sustainability Report, reflecting our company’s

continued commitment to responsible growth and ethical business conduct.

While 2023 marked the foundation of our sustainability efforts, 2024 has been a year of

consolidation and deeper integration of sustainability principles into our business processes.

In 2024, we continued to build on last year’s progress by regularly reviewing how our daily

operations can better support our environmental and social responsibilities.

Building on last year’s achievements, we have realized an internal Sustainable Development

Goals (SDGs) audit that guided our journey forward. We have initiated the process of mapping our contributions and embedding these priorities into

our internal policies.

In parallel, we developed our Policy Book, which includes, in addition to the basic principles

of harmonizing sales and marketing strategies with the production activity needed to sustain

the business, also human approach aspects such as a clear grievance mechanism, an ethics

and anti-corruption policy, key labor commitments. These tools will support transparency,

compliance, and the rights of our employees to a safe and inclusive work environment.

As we move ahead, we remain fully aware that sustainability is not a destination, but a

responsibility. It is a continuous process of improvement, learning, and accountability. We are

proud of the progress we have made—but we are also conscious that the path forward requires

sustained dedication and collaboration.

We remain committed to having a lasting impact—both for our current stakeholders and for the

generations to come.

Iulian Gabriel Mangalagiu – CEO